Hyundai Motor Co. and Kia Corp. have taken a decisive step toward improving electric vehicle safety with a newly disclosed patent that targets one of the industry’s most persistent risks: battery fires.

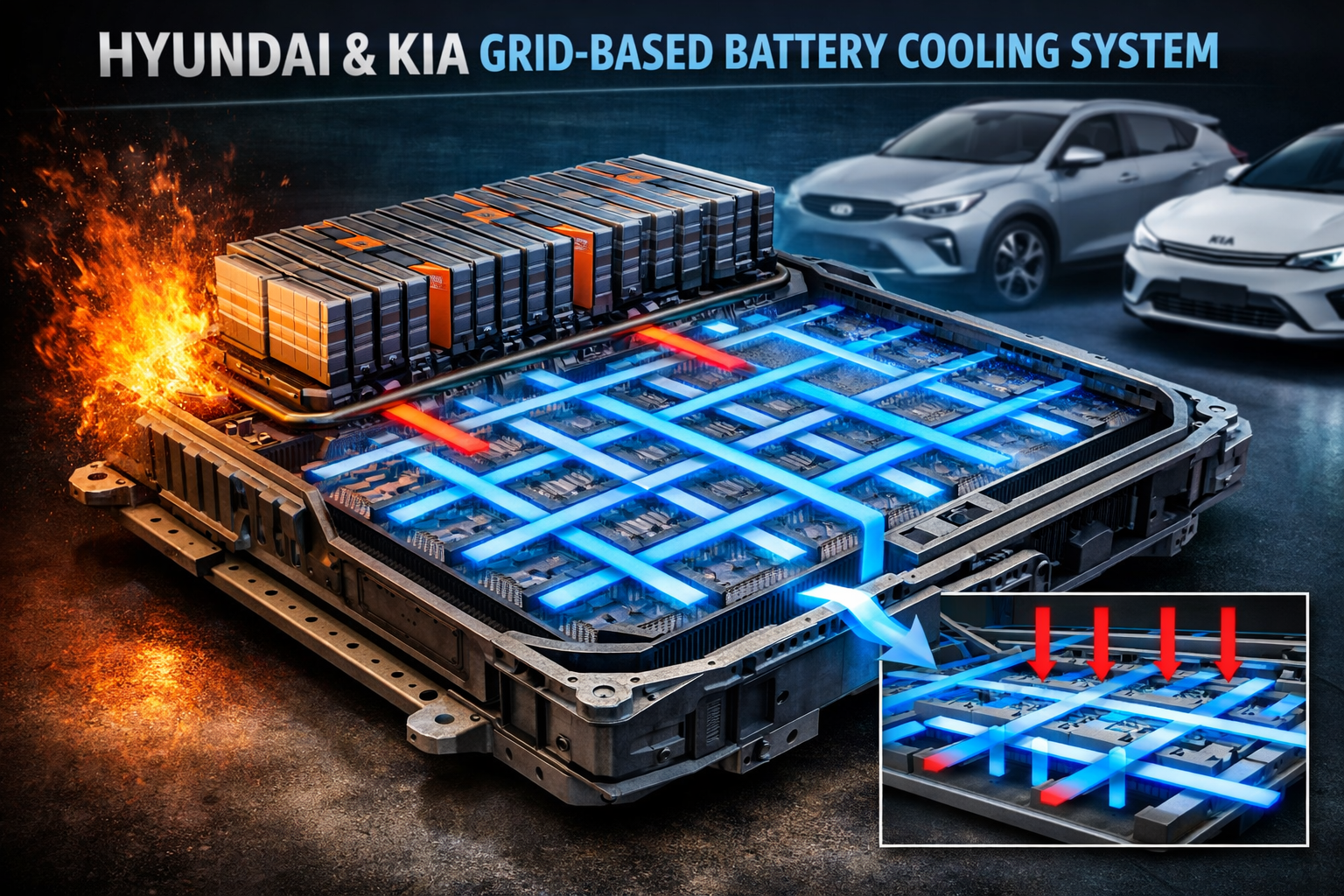

The patent introduces a grid-based cooling system integrated directly into the EV battery case, a design intended to prevent overheating and thermal runaway. The innovation marks a clear departure from conventional battery cooling methods and positions the two automakers at the forefront of next-generation EV safety engineering.

Filed in the United States in November 2024 under the title Battery Storage Case, the patent reflects Hyundai and Kia’s broader push to strengthen battery durability, crash resistance, and thermal stability as electric vehicles move rapidly into the mainstream.

Addressing a Critical Safety Challenge

Battery fires remain a major concern for EV manufacturers, regulators, and consumers. While such incidents are rare, they attract intense scrutiny because lithium-ion battery fires spread quickly and are difficult to control once triggered.

At the core of the problem lies uneven heat distribution. Traditional battery cooling systems often fail to dissipate heat uniformly, allowing localized hotspots to develop. These hotspots can weaken cells, accelerate degradation, and in extreme cases trigger thermal runaway.

Hyundai and Kia’s new patent directly targets this vulnerability.

How the Grid-Based Cooling System Works

The patented design replaces conventional single-direction cooling plates with a multi-directional grid of coolant channels embedded within the lower battery case.

Unlike existing systems that route coolant in straight lines beneath the battery pack, the grid structure allows coolant to flow both horizontally and vertically through intersecting channels. This configuration spreads cooling evenly across the entire battery surface.

The result is tighter temperature control, fewer thermal gradients, and a lower likelihood of isolated overheating.

By integrating the cooling channels into the battery case itself, the design eliminates the need for separate cooling plates and reduces structural complexity.

Cooling and Structure Combined

Beyond thermal management, the patent delivers a significant structural advantage.

Conventional EV battery assemblies rely on layered components. Cooling plates sit beneath battery modules, creating joints that can concentrate mechanical stress during impacts. These interfaces represent potential failure points in crashes.

Hyundai and Kia’s approach merges cooling and structure into a single component. The grid-reinforced battery case distributes loads more evenly across the vehicle’s underbody, improving impact resistance while maintaining efficient heat dissipation.

This dual-function design enhances both safety and durability, particularly in side and underbody collisions where battery damage can have severe consequences.

Comparison with Existing Technologies

Current EV cooling solutions generally fall into three categories:

- Air cooling, which is simple but inadequate for high-performance batteries

- Liquid cooling plates, which improve heat transfer but often suffer from uneven flow

- Advanced systems such as heat pipes or phase-change materials, which add cost and complexity

Hyundai and Kia’s grid-based system builds on liquid cooling but overcomes its key limitation: directional flow. By creating multiple cooling pathways, the system ensures redundancy and uniformity without introducing exotic materials or complex mechanisms.

Compared to traditional cooling plates, the grid design offers:

- More consistent temperature control

- Fewer structural weak points

- Improved resistance to mechanical stress

- Reduced risk of thermal runaway

The simplicity of integration also increases the likelihood of mass-production adoption.

Strategic Importance of the Patent

Securing the patent in the United States is a calculated move. The U.S. remains one of the world’s largest EV markets and enforces strict safety and liability standards. Protecting the intellectual property there gives Hyundai and Kia a competitive advantage while limiting imitation by rivals.

The patent also aligns with broader industry efforts to enhance EV safety. Hyundai and Kia have been working closely with leading battery manufacturers to improve cell stability, thermal monitoring, and system-level protections.

This filing strengthens that ecosystem and signals a long-term commitment to safety-first EV design.

From Concept to Production

While not all patents reach production, industry observers note that the technical detail in this filing suggests near-term applicability. The design relies on existing coolant technologies and manufacturing processes, reducing barriers to deployment.

Analysts expect the grid-based battery case to appear in future Hyundai and Kia electric platforms within the next few model cycles, potentially beginning in the latter half of the decade.

If implemented at scale, the innovation could set a new benchmark for EV battery safety and influence broader industry standards.

Implications for the EV Market

As electric vehicles become the default choice in many markets, safety is emerging as a key differentiator. Consumers now expect EVs to match or exceed internal combustion vehicles in reliability and resilience.

Battery safety innovations such as Hyundai and Kia’s grid-based cooling system play a critical role in building that confidence. By addressing overheating at the structural level, the companies are not merely reacting to incidents but proactively redesigning the foundation of EV architecture.

A Clear Signal to the Industry

Hyundai and Kia’s patent sends a strong message. The future of electric mobility will not be defined by range and charging speed alone. It will be defined by trust, durability, and safety under real-world conditions.

With this grid-based battery cooling case, the two automakers demonstrate how incremental engineering decisions can deliver substantial gains. If adopted widely, the design could reduce fire risks, extend battery life, and reshape how manufacturers think about thermal management in electric vehicles.

In an industry racing toward electrification, Hyundai and Kia have chosen to race toward safety as well.